Bidhaa za kawaida za CNC Machining POM Plastiki

Get Latest Price| Min. Amri: | 1 Bag/Bags |

| Usafiri: | Ocean,Land,Air |

| Min. Amri: | 1 Bag/Bags |

| Usafiri: | Ocean,Land,Air |

Mfano wa Mfano.: PL-094

Marekebisho ya bidhaa za plastiki za POM husababishwa sana na sababu kadhaa:

1. Kubadilisha deformation, nyenzo za POM Tofauti na chuma, kushinikiza kutaleta mabadiliko, machini ya CNC machining kisha kufunguliwa, bidhaa za plastiki za POM zitarudi katika hali yake ya asili.

2. Marekebisho ya mafuta. Joto nyingi hutolewa wakati wa CNC Machining POM , na nyenzo za POM ni nyeti sana kwa joto, na kusababisha uharibifu.

3. Marekebisho ya elastic, ugumu wa nyenzo za POM ni nzuri sana, wakati CNC machining POM , bidhaa za plastiki za POM zitazalisha deformation ya elastic, baada ya zana kuondoka, bidhaa za plastiki za POM zitapata kiwango fulani cha mabadiliko.

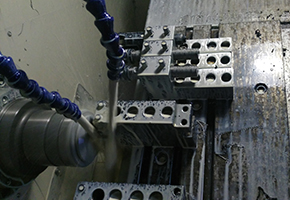

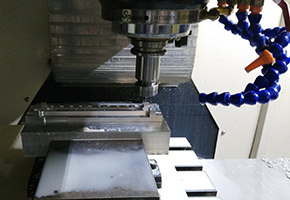

Tunayo timu ya teknolojia ya machining ya CNC iliyojitolea. Michakato ya kiwanda: Mapitio ya agizo, ukaguzi wa kuchora, programu ya CNC ya bidhaa, upangaji wa uzalishaji, machining, ukaguzi wa ubora, ufungaji na usafirishaji. Wafanyikazi wetu wa kiufundi wamekusanya uzoefu mwingi wa kiufundi katika usindikaji wa machining ya plastiki, tuna uchambuzi wa kina wa deformation ya bidhaa katika plastiki ya machining ya CNC . Karibu katika mchakato wote wa plastiki wa CNC , mfanyakazi atafanya muundo wa kudhibiti muundo wa bidhaa.

Buildre Group Co, Ltd imekuwa ikiona ubora kila wakati kama msingi wa ushindani wa biashara, kupitia mfumo mgumu wa usimamizi wa uzalishaji na njia za kudhibiti ubora, kwa msingi wa teknolojia ya ubora wa ubora, na kutoka kwa nyanja zote za utaftaji wa kiwango cha juu.

|

Business content |

CNC miliing, CNC turning |

|

Machining Processes |

CNC Milling, CNC Turning, CAM Programming, Sheet Metal Fabrication, Grinding, Cutting, Thread Turning, Milling Threading, Tapping, Drilling, Knurling |

|

Machining Metal |

Titanium, Aluminum, Copper, Brass, Bronze, Stainless Steel, Steel, Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, PEEK, Acrylic, PMMA,PC, Polycarbonate, PAI, PPS, PA, PET, PEI, PE, PVC, PP, ABS, PEP, PS, PSF, PI, PMMI, PABM, PU. |

|

Parts Size |

Milling Parts ( MAX) : Length 1030mm,Width 800mm, Height 750mm. Turning Parts ( MAX) : Diamter 680mm,Length 750mm. |

|

Tolerance |

0.01mm |

|

Equipment Capabilities |

CNC Machining Center, 3 Axis, 4 Axis, CNC Lathe, Lathe, CNC Turning Centers, Horizontal 8/12-position hydraulic turret, Milling Machine, Grinding Machine, Drill Press, Tapping Center, Rotary Indexer, Punch |

|

Secondary Services of Machining Parts |

Assemble, Plating Zinc Color (Machining Steel Parts), Anodize, Anodize Color, Hard Anodize, Hard Anodize Teflon (Machining Aluminum), Electroless Nicke (Machining Aluminum Parts, Machining Stainless Steel Parts, Machining Brass Parts ), Passivation ( Machining Stainless Steel parts ), Sand Blasting ( Machining Aluminum parts ), Brushed ( Machining Aluminum parts , Machining Stainless Steel parts ), Bluing and Blackening ( Machining Steel parts ), Trivalent Chromium Process ( Machining Aluminum parts ), Welding, brazing, soldering, Centerless Grinding and Burnishing |

|

Sample |

Samples are for free, sample time is 5 days. |

|

Delivery |

Delivery time is 3-4 week, depending on the degree of difficulty of machining parts |

|

file format |

Para-Solid 3D, PDF, IGES, STEP, SOLIDWORKS |

Tunatarajia kuwasiliana nawe zaidi. Kuwa na siku njema na asante kwa uchunguzi wako!

Taarifa ya faragha: Usiri wako ni muhimu sana kwetu. Kampuni yetu inaahidi kutofafanua habari yako ya kibinafsi kwa expany yoyote na ruhusa zako wazi.

Jaza habari zaidi ili iweze kuwasiliana na wewe haraka

Taarifa ya faragha: Usiri wako ni muhimu sana kwetu. Kampuni yetu inaahidi kutofafanua habari yako ya kibinafsi kwa expany yoyote na ruhusa zako wazi.