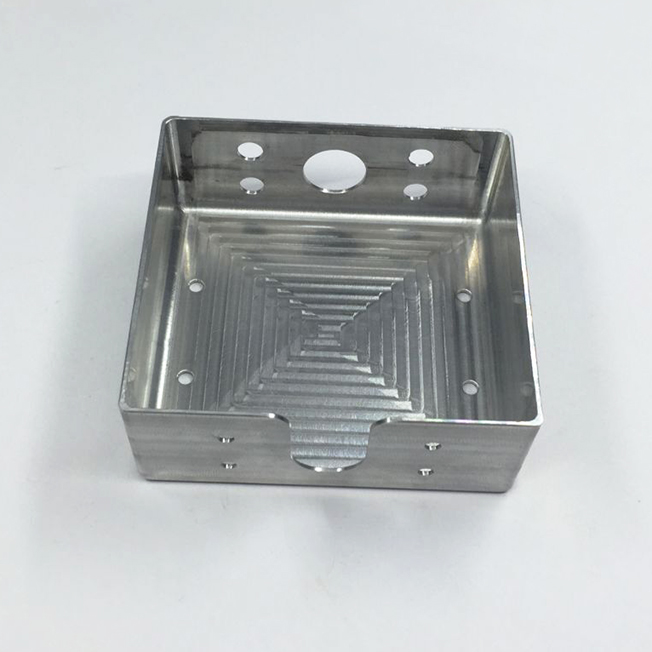

Machining Aluminium Compastment ya tochi

Get Latest Price| Aina ya malipo: | T/T |

| Incoterm: | FOB |

| Min. Amri: | 1 Bag/Bags |

| Usafiri: | Ocean,Land,Air |

| Aina ya malipo: | T/T |

| Incoterm: | FOB |

| Min. Amri: | 1 Bag/Bags |

| Usafiri: | Ocean,Land,Air |

Mfano wa Mfano.: AL-140

Sehemu ya betri ya aluminium ya machining ni aina ya chombo kilichotengenezwa na vifaa vya aloi ya alumini, ambayo hutumiwa kwa kusanikisha betri. Sehemu ya betri ya aluminium ya machining iliyotengenezwa na kampuni yetu hutumiwa kwenye tochi ya uhandisi ya kiwango cha juu. Kwa sasa, vifaa vya kawaida vya betri kwenye soko ni plastiki, chuma cha pua na alumini. Sababu ambayo tunatumia chumba cha betri ya aluminium ya machining ni kwamba ni nyepesi na salama kuliko chuma cha pua na plastiki. Kutoka kwa mtazamo mbaya zaidi, hata kama betri ililipuka, eneo la betri ya alumini ya machining ni dhaifu sana kuliko ganda la chuma na ganda la plastiki, na kusababisha athari ya chini.

Tunaweza kutoa bidhaa za hali ya juu za kugeuza mitambo, ilitokana na mashine ya usahihi na vifaa, mchakato madhubuti wa kudhibiti ubora, usimamizi wa kibinadamu, na timu bora. Mafundi wetu hufanya uchambuzi wa kina wa kila mchoro kulingana na nyenzo za bidhaa, na kuweka vigezo vya mashine, pamoja na: Kukata (Machining) kasi (kasi ya mstari, kasi ya mzunguko), nyenzo za zana, hali ya machining (machining mbaya na kumaliza machining ), kiasi cha kulisha na kina cha kukata.

|

Business content |

CNC miliing, CNC turning |

|

Machining Processes |

CNC Milling, CNC Turning, CAM Programming, Sheet Metal Fabrication, Grinding, Cutting, Thread Turning, Milling Threasing, Tapping, Drilling, Knurling |

|

Machining Metal |

Titanium, Aluminum, Copper, Brass, Bronze, Stainless Steel, Steel, Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, PEEK, Acrylic, PMMA,PC, Polycarbonate, PAI, PPS, PA, PET, PEI, PE, PVC, PP, ABS, PEP, PS, PSF, PI, PMMI, PABM |

|

Parts Size |

Milling Parts ( MAX) : Length 1030mm, Width 800mm, Height 750mm. Turning Parts ( MAX) : Diamter 680mm, Length 750mm. |

|

Tolerance |

0.01mm |

|

Equipment Capabilities |

CNC Machining Center, 3 Axis, 4 Axis, CNC Lathe, Lathe, CNC Turning Centers, Horizontal 8/12-position hydraulic turret, Milling Machine, Grinding Machine, Drill Press, Tapping Center, Rotary Indexer, Punch |

|

Secondary Services of Machining Parts |

Assemble, Plating Zinc Color (Machining Steel Parts), Anodize, Anodize Color, Hard Anodize, Hard Anodize Teflon (Machining Aluminum), Electroless Nicke (Machining Aluminum Parts, Machining Stainless Steel Parts, Machining Brass Parts ), Passivation ( Machining Stainless Steel parts ), Sand Blasting ( Machining Aluminum parts ), Brushed ( Machining Aluminum parts , Machining Stainless Steel parts ), Bluing and Blackening ( Machining Steel parts ), Trivalent Chromium Process ( Machining Aluminum parts ), Welding, brazing, soldering, Centerless Grinding and Burnishing |

|

Sample |

Samples are for free, sample time is 5 days. |

|

Delivery |

Delivery time is 3-4 week, depending on the degree of difficulty of machining parts |

|

file format |

Para-Solid 3D, PDF, IGES, STEP, SOLIDWORKS |

Faida za Machining za CNC ni:

① Idadi kubwa ya zana inaweza kupunguzwa na sehemu zilizo na maumbo ngumu haziitaji zana ngumu. Ikiwa unataka kubadilisha sura na saizi ya sehemu, unahitaji tu kurekebisha taratibu za machining za maendeleo na muundo mpya wa bidhaa.

Ubora Ubora wa machining ni thabiti, usahihi wa machining ni wa juu, kurudiwa ni juu, na inafaa kwa mahitaji ya machining ya ndege.

③ Ufanisi wa uzalishaji ni juu chini ya hali ya aina nyingi na uzalishaji mdogo wa batch, ambayo inaweza kupunguza wakati wa utayarishaji wa uzalishaji, marekebisho ya zana ya mashine na ukaguzi wa mchakato, na kupunguza wakati wa kukata kwa sababu ya matumizi ya kiwango bora cha kukata.

Njia za kawaida za machineble ni ngumu kusindika nyuso ngumu, na zinaweza kusindika sehemu zingine za machining.

Tunatarajia kuwasiliana nawe zaidi. Kuwa na siku njema na asante kwa uchunguzi wako!

Taarifa ya faragha: Usiri wako ni muhimu sana kwetu. Kampuni yetu inaahidi kutofafanua habari yako ya kibinafsi kwa expany yoyote na ruhusa zako wazi.

Jaza habari zaidi ili iweze kuwasiliana na wewe haraka

Taarifa ya faragha: Usiri wako ni muhimu sana kwetu. Kampuni yetu inaahidi kutofafanua habari yako ya kibinafsi kwa expany yoyote na ruhusa zako wazi.